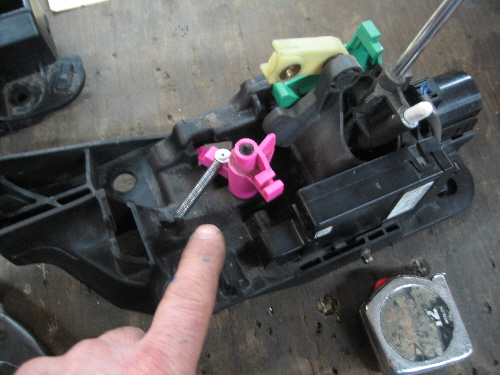

Well since last week I have been spinning my wheels a little and not in a good way. It took me about 5 hours last Saturday to track down why the shifter was locking me out. At first I assumed it was something electrical not releasing the shifter like perhaps the car wanted the doors on an closed or something like that. So I hooked up all of the door harnesses and latches and nothing. The shifter unit is a plastic affair which has a cable that runs to the transmission and a cable that runs to the ignition switch. I decided to try to open the assembly up to at least try to understand it. Inside I found two lock out cams. One (pink) was attached to the cable leading to the ignition switch. This prevents the shifter from being moved to the right to the gear select alley when the key is in the off position. A mechanical neutral safety switch. When the key is on the cable goes slack and the cam is suppose to move out of the way and allow the shifter into the alley. The green cam was actuated by a solenoid and allows the shifter down the alley to the various shift positions. Assuming there was something wrong with the solenoid I isolated it an powered it up and it was fine.

I was stumped until I realized that there was nothing to draw the pink cam back when the cable went slack. It is hard to know when something is missing if you have never seen it before. It turns out there was a tang broken off of it that corresponds to one across from it on the housing. I got a return spring and riveted it to the cam and that seemed to be the trick.

All of this was in pursuit of getting the car running under it's own power so that I could finish getting my North Carolina title. The inspector who had been here a year ago told me that the car did not need to be done. Just get it running under it's own power then give a call for another inspection. I got the car running. I called. He had been reassigned. I got a new guy out. He looked it over and said he would go back and do some paperwork and I would have my title in a couple of weeks.......About 20 minutes later he calls and his boss said "That's the old rule. Now the car must be road worthy. Doors,glass, headlights, blinkers, etc." Massive waste of time.

So the previous Friday I had ordered my wheels and tires. Tuesday I get a call my wheels are in but the guy said they were a little damaged in shipping. Did I want to come in and look at them and they might sell me them at a discount..... Well two of them looked like they had been dropped from a roof on to concrete. The front rims had a 3 inch flat spot. Bottom line I can't believe they would even try to sell me those at any price and they are ordering me another set.

To get my mind back in the game I decided to re build my quarter window rollers and regulator and figure out how it works. I had hoped to modify the existing power window module from the 06 to operate these windows but after seeing the tricks that this set up is designed to do I am going to have to rethink it a bit. The mechanism is really clever in that when it rolls down it has to first retract the glass backwards and then when it pulls it down it rotates the front down faster than the rear in order to accommodate the wheel tub. To all of you veterans of restorations out there I know I am no revealing anything new but I just thought it was pretty spiffy the way it works. Unfortunately for my situation the 06 mechanism is a simple up/down unit that runs on a cabling system. I am not sure the motor is heavy duty enough to engage this old mechanism.